Epoxy resin

for electronics

Well-proven potting compounds, adhesives, sealants and coatings for demanding applications

Wevo epoxy resin systems provide reliable protection for electrical and electronic components – even under extreme thermal and mechanical stress or in harsh environments. If required, we can customise the products to suit your specific needs – for example, in terms of thermal conductivity, flame retardancy, pot life or curing time. Wevo electro potting resins ensure both long-term performance and process reliability.

Epoxy resin potting compounds | Epoxy resin adhesives | Epoxy resin sealants | Insulating coatings

Portfolio at a glance

Whether potting compound, adhesive, sealant or coating – depending on your requirements, our electrically insulating epoxy resins offer reliable protection for electronics and electrical engineering components. For example, our 2K systems enable:

- The use of sensitive electronic components at very high or low temperatures

- Targeted thermal management to prevent overheating and hotspots

- Electronic assemblies to be highly resistant to chemical substances

- Efficient production processes through curing at room temperature, using infrared radiators or ovens

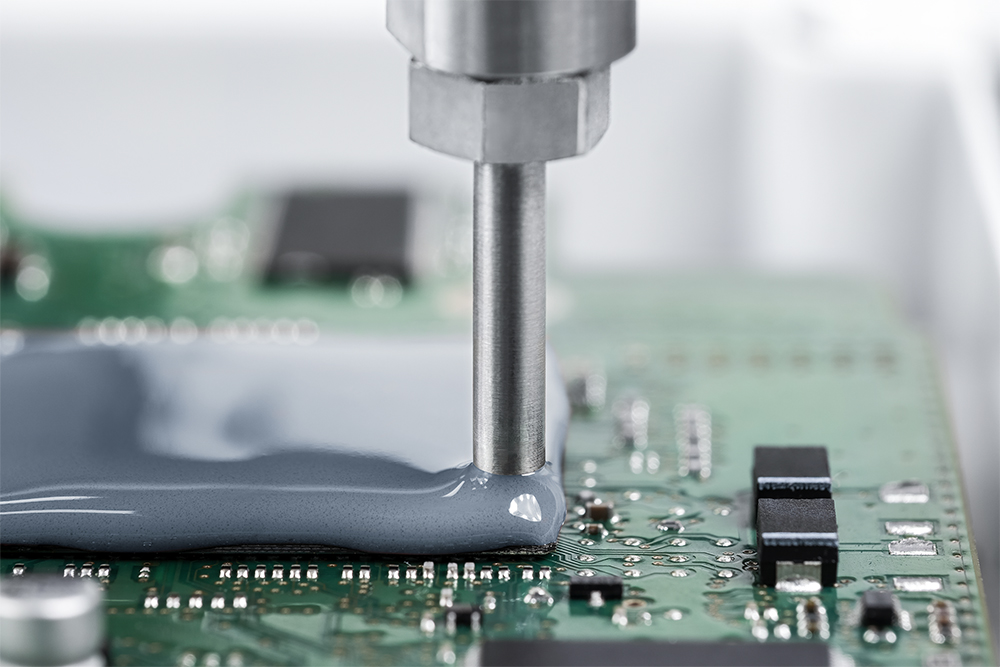

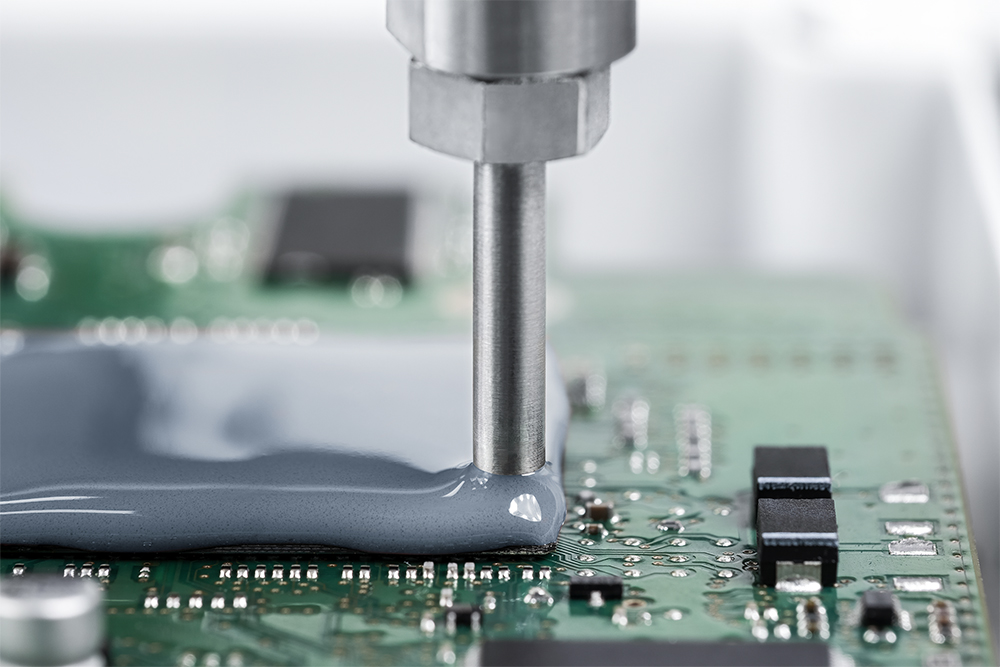

Proven epoxy resin potting compounds for long-term component protection

A 2K electronic potting compound from Wevo ensures excellent insulation and thermal stability. The systems combine high thermal conductivity (up to 2.0 W/m·K) with low viscosity, enabling easy processing and automated production. Flame-retardant or transparent epoxy systems are available on request. Our products are ideal for potting or encapsulating sensitive electronic assemblies in complex applications such as battery management, inverters and sensor technology.

Proven epoxy resin potting compounds for long-term component protection

A 2K electronic potting compound from Wevo ensures excellent insulation and thermal stability. The systems combine high thermal conductivity (up to 2.0 W/m·K) with low viscosity, enabling easy processing and automated production. Flame-retardant or transparent epoxy systems are available on request. Our products are ideal for potting or encapsulating sensitive electronic assemblies in complex applications such as battery management, inverters and sensor technology.

Permanent bonds with customised epoxy resin adhesives

Our epoxy resin-based reactive adhesives bond reliably with a broad range of substrates and can therefore be used without primer for bonding metal or joining plastics. The systems feature high tensile strength with excellent impact resistance, temperature resistance up to 180°C and chemical resistance. In addition, their flexibility can be individually adjusted. Besides black epoxy adhesive, numerous other colours are available on request. Among other applications, these products are suitable for use as potting adhesives, structural adhesives or industrial adhesives for electronic and electrical components.

Permanent bonds with customised epoxy resin adhesives

Our epoxy resin-based reactive adhesives bond reliably with a broad range of substrates and can therefore be used without primer for bonding metal or joining plastics. The systems feature high tensile strength with excellent impact resistance, temperature resistance up to 180°C and chemical resistance. In addition, their flexibility can be individually adjusted. Besides black epoxy adhesive, numerous other colours are available on request. Among other applications, these products are suitable for use as potting adhesives, structural adhesives or industrial adhesives for electronic and electrical components.

Epoxy resin systems made by Wevo offer reliable protection due to their mechanical strength, chemical resistance, or heat-conducting properties – meeting even the most stringent requirements of modern electronics.

Epoxy resin systems made by Wevo offer reliable protection due to their mechanical strength, chemical resistance, or heat-conducting properties – meeting even the most stringent requirements of modern electronics.

Epoxy resin sealants for reliable sealing

Our epoxy resin systems provide reliable protection from environmental hazards such as moisture, oils, fuels, brake and coolant fluids, and aggressive media such as AdBlue. They are ideal for epoxy resin applications in the automotive industry or for outdoor use. Low water absorption, high flexibility, strong adhesion and optimisation for thermal cycles ensure a lasting seal. Liquid to thixotropic epoxy resin sealants can be adapted to ensure efficient manufacturing processes on request.

Epoxy resin sealants for reliable sealing

Our epoxy resin systems provide reliable protection from environmental hazards such as moisture, oils, fuels, brake and coolant fluids, and aggressive media such as AdBlue. They are ideal for epoxy resin applications in the automotive industry or for outdoor use. Low water absorption, high flexibility, strong adhesion and optimisation for thermal cycles ensure a lasting seal. Liquid to thixotropic epoxy resin sealants can be adapted to ensure efficient manufacturing processes on request.

Insulating coatings for sensitive electronic components

Wevo epoxy resin coatings provide protection for surfaces, cure without cracking and allow for thin layer thicknesses, even those with high solid content. Result: long-term mechanical stability and dielectric strength. They ensure that components operate reliably and also offer high chemical resistance to many substances or flame-retardant properties in accordance with UL 94 V-0 and can withstand temperature fluctuations. Apart from coloured variants, transparent epoxy resin coatings are also available.

Insulating coatings for sensitive electronic components

Wevo epoxy resin coatings provide protection for surfaces, cure without cracking and allow for thin layer thicknesses, even those with high solid content. Result: long-term mechanical stability and dielectric strength. They ensure that components operate reliably and also offer high chemical resistance to many substances or flame-retardant properties in accordance with UL 94 V-0 and can withstand temperature fluctuations. Apart from coloured variants, transparent epoxy resin coatings are also available.

Impressed? Then get in touch with us today!

WEVO Chemical (Asia-Pacific) Pte. Ltd. is the ideal partner to supply epoxy resin for electronics and electrical engineering applications. Our experts will be happy to advise you and answer any questions you may have about our services and products.

Just send us your enquiry via Email.

Impressed? Then get in touch with us today!

WEVO Chemical (Asia-Pacific) Pte. Ltd. is the ideal partner to supply epoxy resin for electronics and electrical engineering applications. Our experts will be happy to advise you and answer any questions you may have about our services and products.

Just send us your enquiry via Email.

Epoxy resin applications at a glance

Wevo is an experienced manufacturer of reliable potting compounds, adhesives and sealants. Our resins are used in a wide range of electronic applications for sectors such as the automotive industry and energy technology.

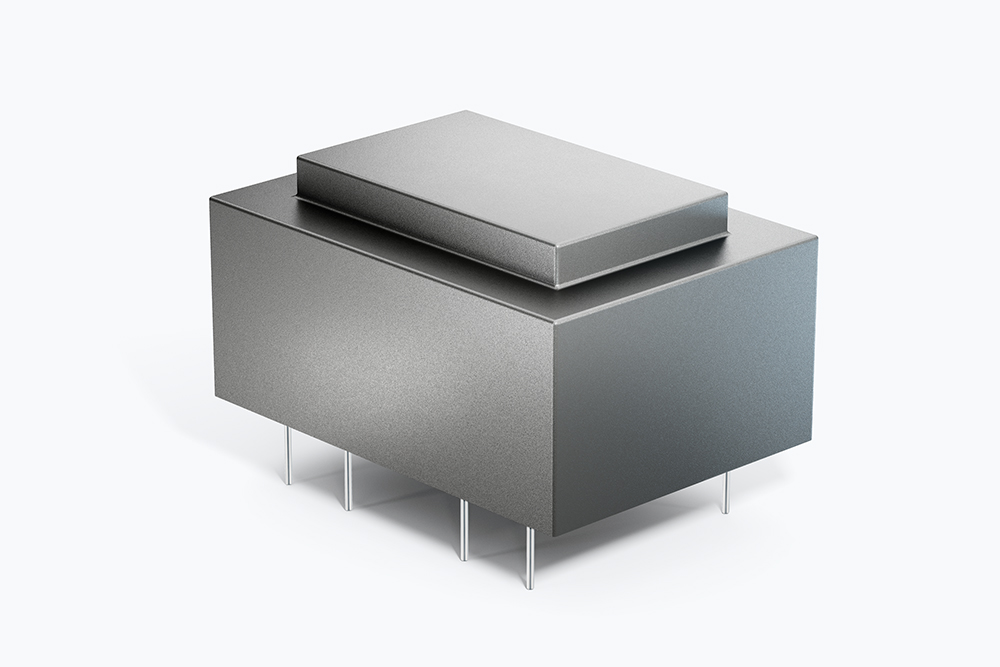

Protection for electronics with customised 2K potting compounds

Special epoxy resins for sensor potting enable efficient production and reliable operation for state-of-the-art electronic components. Moreover, the electro potting resins have excellent mechanical and electrical properties, which means high-performance transformers are guaranteed to function reliably, even under extreme conditions.

Protection for electronics with customised 2K potting compounds

Special epoxy resins for sensor potting enable efficient production and reliable operation for state-of-the-art electronic components. Moreover, the electro potting resins have excellent mechanical and electrical properties, which means high-performance transformers are guaranteed to function reliably, even under extreme conditions.

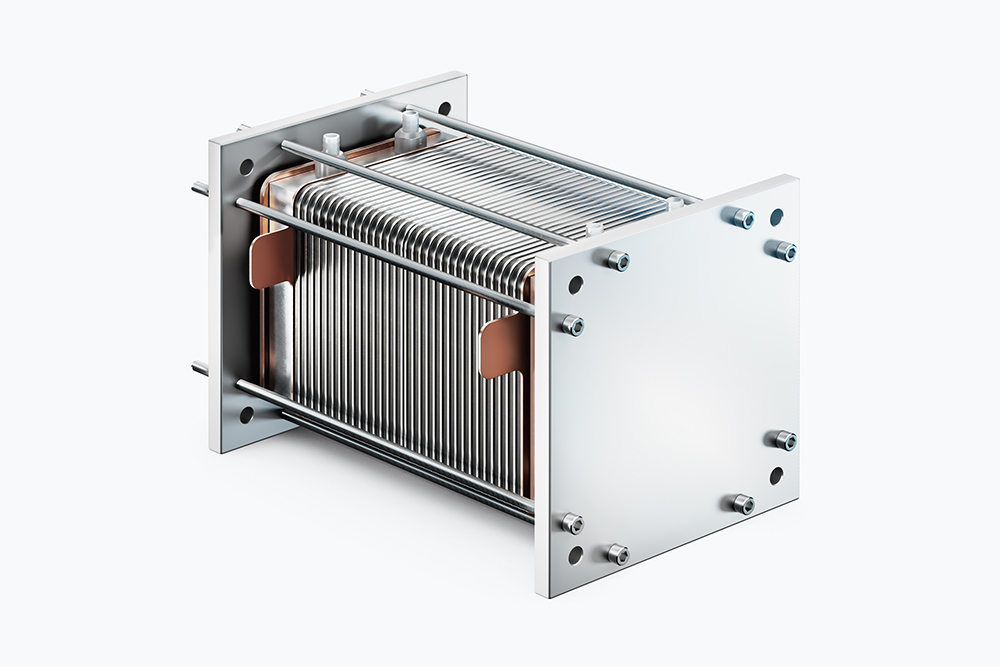

Wevo epoxy resin for battery components

As an alternative to conventional elastomer gaskets, liquid sealants made by Wevo facilitate the automated production of redox flow batteries – ensuring a significantly more efficient production process. At the same time they provide a new level of freedom in terms of design, a fact underlined in a study conducted by the Fraunhofer Institute for Chemical Technology (ICT). The materials offer customised solutions for the cell stack and other components such as current collectors, pumps, flow meters and power electronics.

Wevo epoxy resin for battery components

As an alternative to conventional elastomer gaskets, liquid sealants made by Wevo facilitate the automated production of redox flow batteries – ensuring a significantly more efficient production process. At the same time they provide a new level of freedom in terms of design, a fact underlined in a study conducted by the Fraunhofer Institute for Chemical Technology (ICT). The materials offer customised solutions for the cell stack and other components such as current collectors, pumps, flow meters and power electronics.

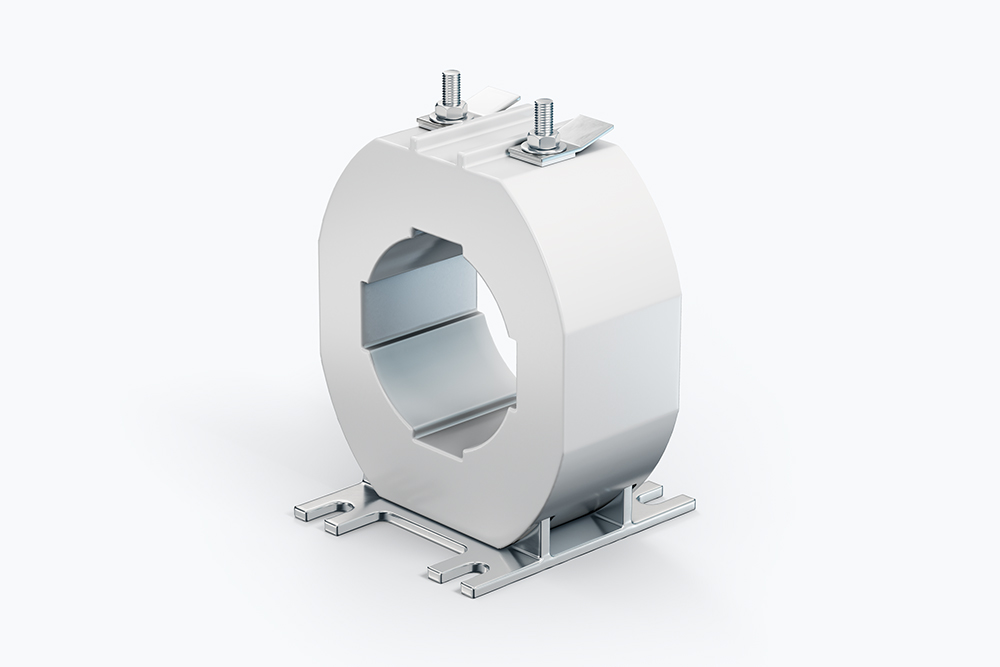

Reactive plastic systems for potting, bonding and sealing modern energy technology

Our 2K epoxy resin potting compounds provide electrical insulation and adaptable dielectric properties for high-voltage transducers. They can also withstand high temperatures and a great number of thermal cycles, providing lasting moisture protection for the electronics. As specially optimised thermally conductive materials, electronic potting compounds provide effective thermal management and help to ensure reliable long-term performance. Our epoxy resin systems also open up new possibilities for a wide range of other energy technology applications.

Find out more

Reactive plastic systems for potting, bonding and sealing modern energy technology

Our 2K epoxy resin potting compounds provide electrical insulation and adaptable dielectric properties for high-voltage transducers. They can also withstand high temperatures and a great number of thermal cycles, providing lasting moisture protection for the electronics. As specially optimised thermally conductive materials, electronic potting compounds provide effective thermal management and help to ensure reliable long-term performance. Our epoxy resin systems also open up new possibilities for a wide range of other energy technology applications.

Find out more

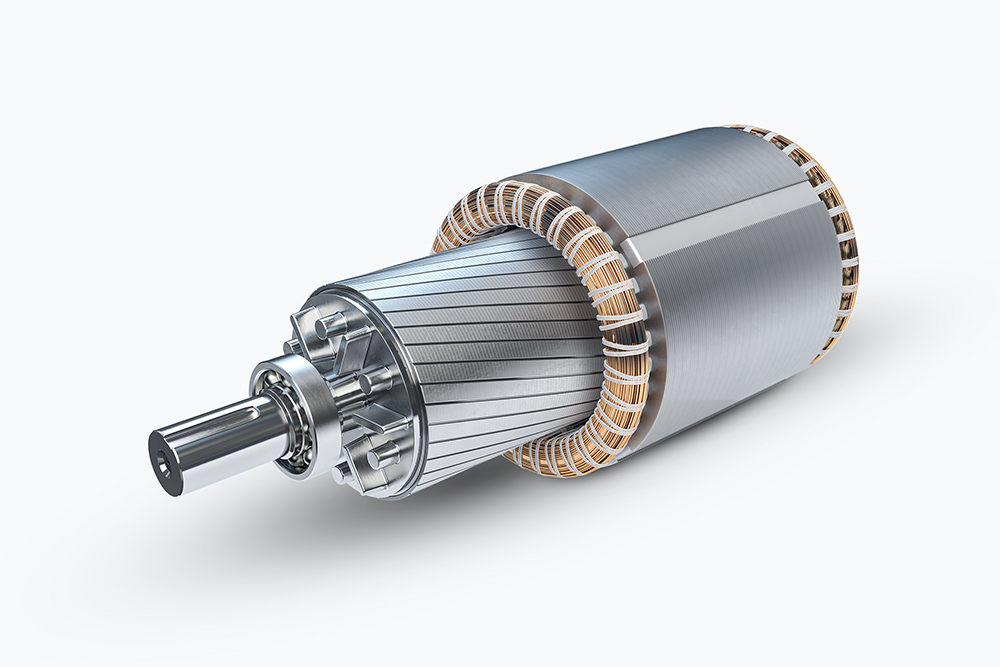

High-performance epoxy resins for electric motor encapsulation

Wevo has developed thermally conductive electronic potting resins for stators and winding heads, enabling an efficient automated potting process and high power densities. Moreover, among their other properties, 2K potting resins provide excellent thermal stability, thermal shock resistance and ensure reliable electrical insulation in the high-voltage range (> 25 kV/mm dielectric strength).

Find out more

High-performance epoxy resins for electric motor encapsulation

Wevo has developed thermally conductive electronic potting resins for stators and winding heads, enabling an efficient automated potting process and high power densities. Moreover, among their other properties, 2K potting resins provide excellent thermal stability, thermal shock resistance and ensure reliable electrical insulation in the high-voltage range (> 25 kV/mm dielectric strength).

Find out more

Why epoxy? Properties and advantages

Epoxy resins (EP resins for short) are thermosetting plastics that cure by means of a chemical reaction with suitable hardeners in a defined mixing ratio. Reactive cross-linking (polymerisation reaction) results in a material with high network density, mechanical strength, chemical resistance and thermal stability. Wevo epoxy resin systems also offer a number of key advantages:

- Customisable properties: including viscosity, pot life, thermal conductivity, electrical conductivity, flame retardancy, colour

- Excellent electrical insulation: above-average dielectric strength and low dielectric constant

- High resistance to thermal cycling and temperature changes: stable mechanical and electrical properties after hundreds of cycles, e.g. between –40°C and +180°C

- High media resistance: particularly resistant to moisture and chemicals such as automotive fluids (oils, brake fluids, fuels)

- Thermal epoxy resins available: up to 2 W/m·K with excellent flow properties

Why epoxy? Properties and advantages

Epoxy resins (EP resins for short) are thermosetting plastics that cure by means of a chemical reaction with suitable hardeners in a defined mixing ratio. Reactive cross-linking (polymerisation reaction) results in a material with high network density, mechanical strength, chemical resistance and thermal stability. Wevo epoxy resin systems also offer a number of key advantages:

Customisable properties: including viscosity, pot life, thermal conductivity, electrical conductivity, flame retardancy, colour

Excellent electrical insulation: above-average dielectric strength and low dielectric constant

High resistance to thermal cycling and temperature changes: stable mechanical and electrical properties after hundreds of cycles, e.g. between –40°C and +180°C

High media resistance: particularly resistant to moisture and chemicals such as automotive fluids (oils, brake fluids, fuels)

Thermal epoxy resins available: up to 2 W/m·K with excellent flow properties

Product examples: Technical data for selected epoxy resin systems

As an experienced manufacturer of epoxy resin based in Germany, we are committed to delivering uncompromising quality, enabling customised 2K electrical potting compounds to be used in even the most demanding applications. Our reactive plastic systems comply with strict guidelines and standards, including RoHS and REACH, as well as UL 94 and EN 45545-2 certifications without the use of halogenated flame retardants.

| Product category | Epoxy resin potting compound | Epoxy resin adhesive | Epoxy resin sealant | Epoxy resin coating |

| WEVOPOX | 36001 FL | A 50 | 32702 | VE |

| WEVODUR | 5001 | BX | 5008 | 263 |

| Operating temperature [°C] | –40 up to +180 | –25 up to +120 | –40 up to +130 | –30 up to +130 |

| Flammability 94 UL | V-0 2 mm | HB | HB | HB |

| Shore hardness D | 85–90 | 80–85 | 82–90 | 80–85 |

| Thermal conductivity [W/m·K] | 1.1 | 0.2 | 0.3 | 0.2 |

| Mixed viscosity [mPa·s] | 3,500 – 6,500 | 12,000 – 18,000 | 2,000 – 3,500 | 500 – 700 |

| Special property | Approvals according to UL 94 and EN 45545-2 | Excellent adhesion to various substrates | High chemical resistance | Excellent flow properties |

Downloads

Details about our epoxy resin systems – including excerpts from their technical data sheets – are available in our product brochure:

Downloads

Details about our epoxy resin systems – including excerpts from their technical data sheets – are available in our product brochure:

You may also be interested in

Industries

Our products are used in pioneering technologies in a wide range of industries.

Industries

Our products are used in pioneering technologies in a wide range of industries.